Innovative Manufacturing Techniques: In-Mold Decorations Explained

Innovative Manufacturing Techniques: In-Mold Decorations Explained

Blog Article

Grasping In-Mold Decorations: Methods, Fads, and Best Practices for Ideal Results

In the world of production, the art of in-mold decorations stands as an essential facet of item style and production. In-Mold Decorations. By delving into the approaches, patterns, and finest methods that underpin successful in-mold design processes, services can open a realm of opportunities that not just elevate the visual appeal of their items however likewise enhance manufacturing efficiency and strengthen customer engagement.

Material Choice

Material option is an important aspect of understanding in-mold decors, as it straight affects the top quality and sturdiness of the end product. When selecting materials for in-mold decorations, it is vital to take into consideration elements such as compatibility with the molding process, the preferred aesthetic result, and the ecological problems the product will certainly face. Thermoplastic materials like polycarbonate, polypropylene, and abdominal are commonly used for in-mold decors due to their versatility and capacity to achieve elaborate layouts. These products use outstanding moldability, making it possible for makers to create complicated shapes and patterns with accuracy.

In addition, the selected product should have excellent bond homes to ensure that the decoration sticks securely to the substratum during the molding procedure. Adhesion between the material and the design is vital for avoiding delamination and ensuring durable aesthetic charm. Furthermore, products with high heat resistance are liked for in-mold decors, particularly for products that will certainly be subjected to elevated temperatures throughout their lifecycle. By carefully picking the proper product for in-mold decors, suppliers can boost the total quality and sturdiness of their products, meeting the expectations of both clients and end-users.

Layout Development

An essential consider advancing the field of in-mold decorations is the continual expedition and implementation of style development techniques. Layout technology plays a vital duty in improving the aesthetic charm, performance, and overall quality of items produced utilizing in-mold decor procedures. By including cutting-edge layout aspects, makers can distinguish their products out there, draw in consumers, and remain ahead of rivals.

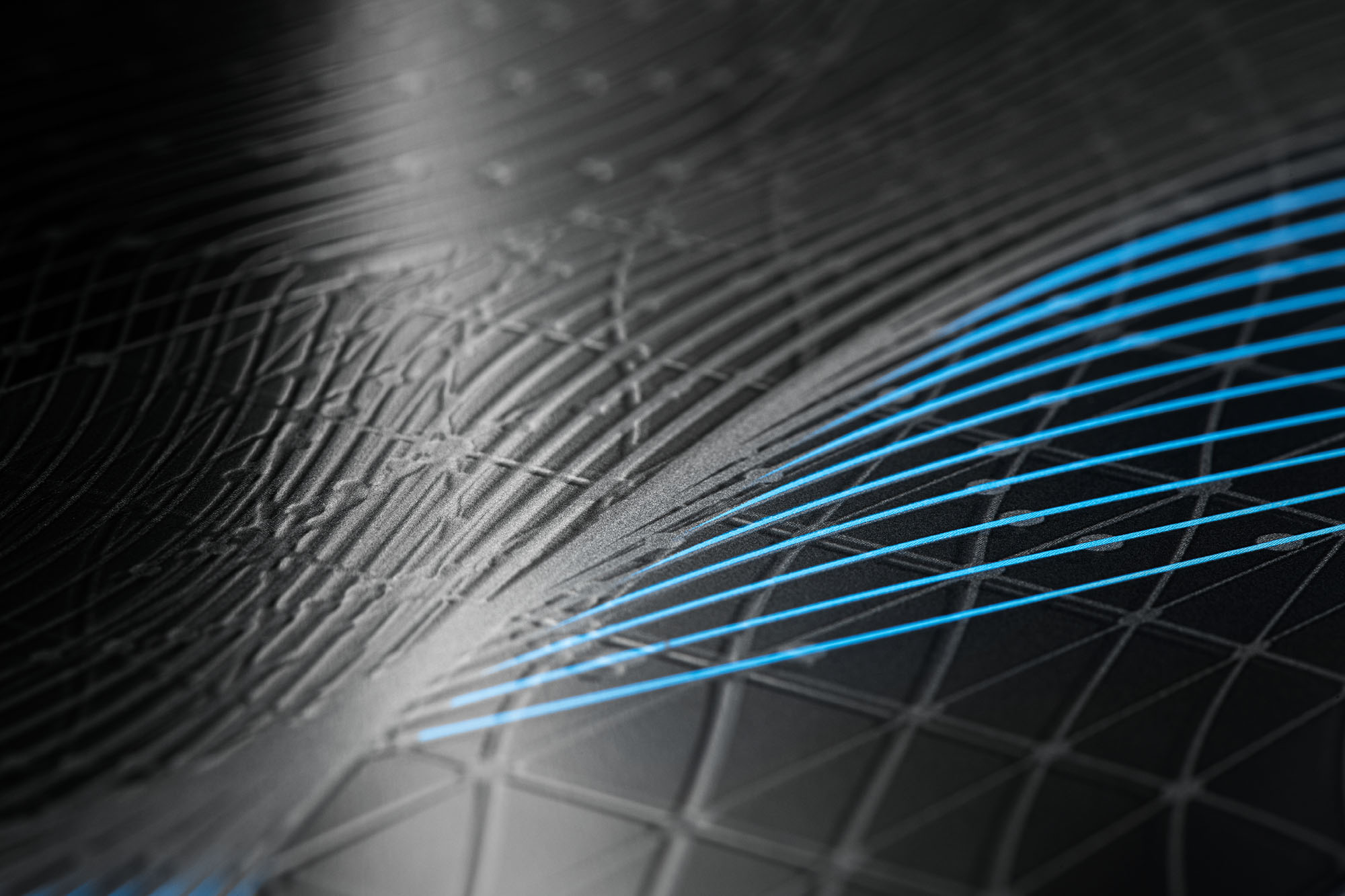

Among the key aspects of layout technology in in-mold designs is the combination of detailed patterns, textures, and graphics that were formerly testing to accomplish with standard decoration techniques. Advanced technologies such as 3D printing and electronic layout tools allow developers to create complicated and detailed designs that can be flawlessly transferred onto molded parts. Furthermore, making use of vibrant shades, metallic finishes, and unique results like gloss or matte structures can additionally raise the visual allure of in-mold embellished products.

In addition, style advancement extends beyond looks to include functional enhancements such as ergonomic forms, integrated attributes, and adjustable components that cater to details customer needs. By accepting design advancement, suppliers can open new possibilities for product, creativity, and customization differentiation in the affordable landscape of in-mold decors.

Production Efficiency

Effective manufacturing procedures are necessary for converting the ingenious designs established in the field of in-mold decorations into premium ended up items that meet market demands and consumer expectations. In the realm of in-mold designs, manufacturing performance incorporates different key aspects that add to the overall success of the production process.

Automation not just accelerates the production procedure however also improves precision and repeatability, leading to an extra consistent and top quality end product. Generally, an alternative technique to production performance is critical in making the most of the potential of in-mold decor methods and achieving optimum results in the affordable market landscape.

Quality Assurance Actions

What are the vital methods for making certain strict top quality control actions in the world of in-mold designs? Quality control steps are extremely important in in-mold decoration procedures to ensure the production of premium and remarkable completed items.

Using advanced innovations such as automated inspection systems can additionally enhance the top quality control process by supplying trusted and exact data for evaluation. These systems can find imperfections that might be missed by manual assessments, thereby improving total product top quality and uniformity.

Routine training and development programs for staff members included in the in-mold decor procedure click site can additionally add to preserving Recommended Site top notch requirements. By enlightening team on ideal practices, top quality assumptions, and the importance of attention to detail, business can promote a culture of quality consciousness throughout the organization.

Customer Charm

To boost the bankability of in-mold decoration items, providing and comprehending to consumer preferences play an important function in determining their charm and success. Supplying personalization options such as tailored styles, shade variations, and textural elements can considerably improve the allure of in-mold decoration products.

Verdict

In-mold decors supply a effective and functional means to enhance item aesthetic appeals. Mastering in-mold decors calls for a holistic method that takes into consideration all facets of the production procedure to make sure success.

In the realm of manufacturing, the art of in-mold designs stands as an essential aspect of product style and production. Design innovation plays an important duty in enhancing the visual charm, functionality, and general quality of items produced using in-mold design procedures.One of the vital aspects of design development in in-mold decors is the integration of intricate patterns, appearances, and graphics that were previously testing to achieve with traditional design techniques.Effective manufacturing procedures are crucial for converting the cutting-edge designs established in their website the area of in-mold decorations into premium completed products that fulfill market demands and consumer expectations. Offering modification options such as individualized styles, shade variants, and textural elements can substantially enhance the allure of in-mold decor items.

Report this page